Product Features

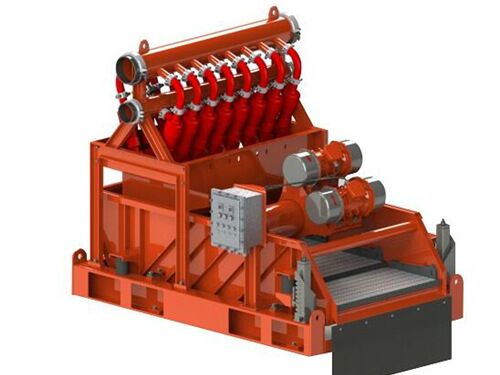

KESMI desilter is the second-stage and the third-stage solid control equipment to treat the drilling fluid. According to the size of the cone diameter, it is divided into Desander and Desilter. Usually the cone diameter less than 6’’ is called desilter, and used as the third-stage control equipment in drilling operation. We commonly used 4″and 6″ cones desander to separate solid-phase particle size 15-40μm in the drilling fluids.

Abrasion resistance polyurethane hydro-cyclones are applied to the unit. The unit can be stand alone for use or assembled above shale shaker through pre-designed connectors. The number of desilter cones is customizable according to the work conditions.

Technical parameters of desilter cyclones:

| Model | Capacity | Desilter Cone Size | Number of Desilter | Working Pressure | Feeding/Output |

| 8N | 120 (m3/h) | 4 (in) | 8 (ea) | 0.25-0.4 (Mpa) | 6 / 8 (in) |

| 12N | 240 (m3/h) | 4 (in) | 12 (ea) | 0.25-0.4 (Mpa) | 6 / 8 (in) |

| 16N | 360 (m3/h) | 4 (in) | 16 (ea) | 0.25-0.4 (Mpa) | 6 / 8 (in) |

Technical parameters of desilter cleaner:

| Model | KSZJ112-8S/12N | KSZJ113-8S/12N/16N | KSZJ114-12N/16N |

| Treating capacity (m3/h) | 120/240 | 120/240/360 | 240/360 |

| Desander Cyclone Size | 4″ | 4″ | 4″ |

| Desander Cyclone Qty | 8/12 | 8/12/16 | 12/16 |

| Work Pressure (Mpa) | 0.25-0.40 | 0.25-0.40 | 0.25-0.40 |

| Inlet Size/outlet size | 6’’ / 8’’ | 6’’ / 8’’ | 6’’ / 8’’ |

| Matching Shaker | KSZS112 | KSZS113 | KSZS114 |

| Weight(kg) | 1080/1120 | 1614/1654/1698 | 1868/1912 |

| Dimensions(mm) | 1718x1470x1682 | 2058x1762x2122 | 2058x1762x2122 |

Technical features of desilter hydrocyclones

- Silt-sized solids removal (15 ~ 74 microns)

- 100% polyurethane hydrocyclone

- 80 gpm per cone at 75 feet of head

- Variable size apex inserts

- Available with and without a ramp in the feed inlet

- Flexible fast connection is available for user to assemble

- Compact design, small footprint