Product Features

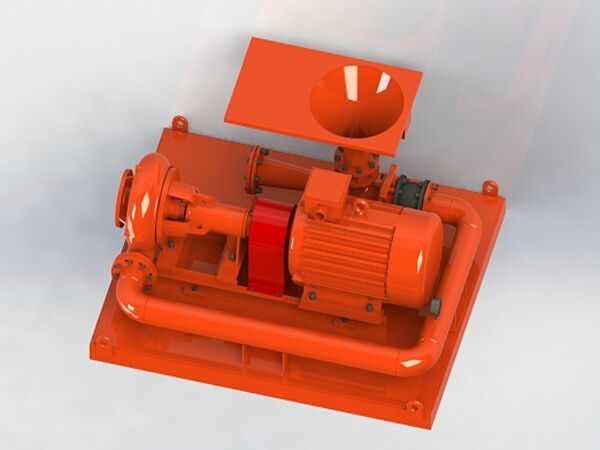

Jet Mud mixer is designed to mixing the barite or bentonite into the drilling fluids and adjust the mud density / mud viscosity to fulfill the drilling target. Single Jet Mud mixer is composed of one set centrifugal pump, one set mixing hopper (verturi hopper) and one set electrical control panel. (The pump control can also design into system control panel). Double Jet Mud Mixer is composed of double pumps and double hoppers, connected by manifold valves and hoses to achieve large mixing capacity target.

According to the job request, the Jet Mud mixer can be used to mixing barite to increase the drilling mud density; Also, Jet Mud mixer can be used to mixing bentonite to increase the drilling mud viscosity. KESMI Jet Mud mixer can be used to work for oil & gas drilling mud system, HDD mud cleaning system, TBM mud purification system, Pipe jacking mud plant etc.

Technical Parameters of Jet Mud mixer

| Model | Flow(m3/h) | Motor power(kw) | Inlet / outlet | Weight (kg) | Dimension(mm) |

| KSSL-045 | 45 | 11 | DN100 / DN100 | 977 | 1850x1540x950 |

| KSSL-055 | 55 | 15 | DN100 / DN100 | 997 | 1850x1540x950 |

| KSSL-065 | 65 | 18.5 | DN100 / DN100 | 1045 | 1850x1540x950 |

| KSSL-090 | 90 | 22 | DN125 / DN100 | 1136 | 1850x1540x930 |

| KSSL-120 | 120 | 30 | DN125 / DN150 | 1340 | 2200x1840x1020 |

| KSSL-150 | 150 | 37 | DN150 / DN150 | 1492 | 2200x1840x1060 |

| KSSL-200 | 200 | 45 | DN150 / DN150 | 1582 | 2200x1840x1060 |

| KSSL-272 | 272 | 55 | DN200 / DN150 | 1732 | 2200x1840x1020 |

| KSSL-320 | 320 | 75 | DN200 / DN150 | 2062 | 2200x1840x1070 |

Technical Features of Jet Mud mixer

- Working pressure range: 0.25~0.4 Mpa

- Both Ex-proof / Non Ex-proof standard available;

- Ex-proof standard can choose EXdIIBt4/IEC/ATEX for option

- Centrifugal pump is interchangeable with NOV Mission pump, help customer to source the spares locally

- High precision machining pump with anti-wearing production material help to get better performance

- High quality mechanical seal to prevent pump leakage and reduce the maintenance

- Top brand bearing for the centrifugal pump, stable operation with longer service life

- 3 layers Marine anti-corrosion paintings is for option

More information about mixing hopper

Mixing Hopper is part of mixing system working together with centrifugal pump. The hopper can be produced by carbon steel or stainless steel. Additional valves can be designed on the hopper to achieve special requirement.

Technical Parameters of Mixing Hopper

| Model | KLD-150S | KLD1-2 |

| Flow rate (m3/h) | 240 | 180 |

| Work Pressure(Mpa) | 0.25-0.45 | 0.25-0.45 |

| Hopper Diameter (mm) | 620 | 708 |

| Inlet/Outlet Diameter (mm) | 150 / 150 | 150 / 150 |

| Mixing Pump Power (kw) | 55 | 55 |

| Solid Phase Mixing Capacity |

|

|

| Liquid Inhalation Capacity | 25m3/h, similar to the chemical liquid of water | N/A |

| Weight (kg) | 265 | 185 |

| Dimension (mm) | 1250×752×1000 | 1518×708×980 |

Technical Features of Mixing Hopper

- KLD-150S mixing unit is equivalent to SWACO Hiride Eductor. KLD-150S integrates a proprietary

- minimum pressure drop (MPD) nozzle and unique trimix diffuser (TMD) into an easily installed, rugged,

- Stainless steel frame which has been designed to an optimal height for improved ergonomics.

- Equipped with wear resistant imported PU material

- Rapid complete mixing of dry or liquid additives into the fluids system

- Lowest comparable pressure loss

- Creates high shear rates in a circulating loop

- Compact design with smaller footprint, ideal for rigs where space is at a premium

- Dust free, dry product mixing

- Minimize “ fish eyes ” in hard to mix products

- Flexible design eliminates extra equipment

- Greater degree of worker safety