Drilling Cuttings Treatment

KESMI drilling waste system is mainly target on the OBM drilling cuttings discharged from solids control shale shakers, to recover the valuable oil-based mud for reuse, reduce the oil on cuttings and minimize the volume of drill cuttings in order to save transportation cost and following treatment cost. Applied to OBM cuttings, the system can reduce the OOC- oil on cuttings to 3~5%.

Product Features

Drilling Cuttings Treatment Unit is applied to OBM cuttings treatment, to recover the valuable oil-based mud for reuse, reduce the oil on cuttings and minimize the volume of drill cuttings in order to save transportation cost and following treatment cost. Applied to OBM cuttings, the system can reduce the OOC- oil on cuttings to 3~5%. The OBM cuttings can be from shale shaker discharges, mud pit OBM cuttings, Tank OBM cuttings etc.

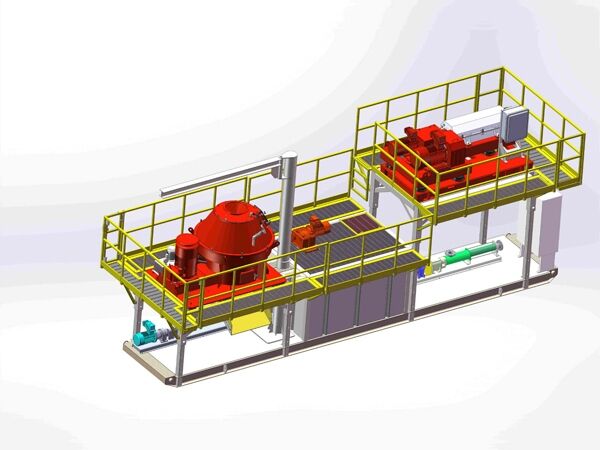

Drilling Cuttings Treatment Unit consist of Vertical cuttings dryer, centrifuges, screw conveyors and transfer pumps for form a pre-designed system, plug and play. With over 10years experience in the design and manufacturing, we adopt high standard equipment to make a robust design unit suitable for tough area applications.

KESMI Drilling Cuttings Treatment Unit Technical Parameters

| Model | DCTU-30 |

| Design Type | Skid Mounted |

| Capacity | 30~50 tons/hour |

| OOC – Oil on cuttings after treatment | 3~5% |

| Equipment for primary treatment | KSCD930C Vertical Cutting dryer |

| Equipment for secondary treatment | KSLW363C Decanter Centrifuge |

| Cuttings transfer | Screw conveyors with different size |

| Fluids transfer | Netzsch brand Nemo pumps |

| Skid | Fixed height skid for VCD and telescopic skid for Centrifuge |

| Mud Skips | Used to collect the cuttings discharged from vertical dryer |

| Other accessories | For optional, can be supplied per request |

Technical Features of KESMI Drilling Cuttings Treatment Unit

- Excellent design based on many years application experience

- Self-deigned main equipment to guarantee on the performance

- Robust produced Vertical cuttings dryer with long-term good performance

- Robust produced Decanter Centrifuge with VFD Smart Control

- Robust produced screw conveyors to minimize the down time

- Germany brand Netzsch brand Pumps to ensure the smooth transfer

- Electrical motors with different certificates, CNEX, IECEX and ATEX