Product Features

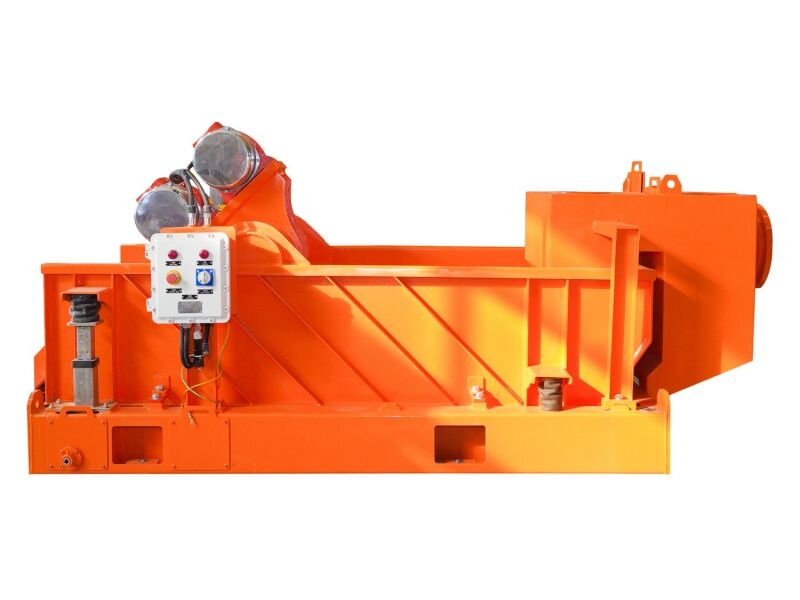

Shale shaker is first phase solids control equipment in drilling fluids processing system, also known as key solids control equipment in drilling mud system, shale shaker decides performance of the complete solids control system.

The shale shaker has different configurations to work with different drilling requirements. The two-panel shaker can work for small rig drilling operation. The three-panel shaker can work with oil drilling / water well drilling / HDD. The four-panel shaker can work for oil drilling operation / waste management to achieve much dryer drilling cuttings.

Technical Parameters of Shale Shaker

| Model | KSZS112-MM | KSZS113-MB | KSZS114-MP | KSZS114-MD |

| Vibrating Mode | Linear motion | Linear motion | Linear motion | Linear motion |

| Max. Capacity (m3/h) | 70 | 110 | 140 | 140 |

| Vibrating Motor (kw) | 2×0.75 | 2×1.5 | 2×1.72 | 2×1.94 |

| Adjusting G force (G) | ≤7.0G | ≤7.5G | ≤7.5G | ≤8.0G |

| Vibration Amplitude (mm) | 3.92~5.62 | 4.14~5.96 | 4.4~6.34 | 4.4~6.34 |

| Deck Adjustment | +2° | -2°~+5° | -2°~+5° | -2°~+5° |

| Screen Qty (pcs) | 2 | 3 | 4 | 4 |

| Screen Size(mm) | 750×900 | 585×1165 | 585×1165 | 585×1165 |

| Screen Area (m2) | 1.35 | 2.04 | 2.73 | 2.73 |

| Weir Height (mm) | 710 | 885 | 885 | 885 |

| Weight (kg) | 893 | 1340 | 1553 | 1520 |

| Dimension(mm) | 1715x1360x1090 | 2322x1650x1400 | 2912x1650x1425 | 2650x1650x1425 |

Technical Features of Flat screen Shale shaker

- Liner Motion, Balance Elliptical Motion and Dual Motion available.

- Capable to deal with heavy mud in large feeding capacity

- Shaker deck angle adjustable while working, mechanical deck angle adjustment with reliable performance.

- Shale shaker bottom deck made from Stainless Steel for long service life.

- Heat treatment on complete shale shaker deck for High G force operation.

- Pretension shaker screen for fast screen replacement, shaker size equivalent to Swaco Mongoose

- Famous Brand Vibration Motors: Italy OLI or US Martin brand motors

- Main electrical components is sourced from premium brands: SIEMENS, Schneider or ABB available

- Different type shaker available for different application

Read More Information about KESMI Shale Shaker

Shale shaker is a key equipment in the solid control system, mainly used to separate drilling cuttings in the drilling fluid, ensuring stable performance of the drilling fluid. It plays a crucial role in drilling operations, improving drilling efficiency, reducing drilling costs, and protecting the environment.

-

Working principle of shale shaker

The vibrating screen generates high-frequency vibration through vibration motor, causing the drilling fluid to flow on the screen. Solid particles (such as drill cuttings) in drilling fluid are intercepted by screens and discharged to the mud pit, while clean drilling fluid go through the mesh and drop down to the beneath tank. The screening efficiency of shale shaker depends on the mesh size, vibration frequency, and amplitude of the screen.

-

Main structure of shale shaker

A shale shaker usually consists of the following parts:

- Screen box: The main structure that supports the shaker screen and vibration mechanism, usually made of steel, with sufficient strength and rigidity.

- Shaker screen: a key component used to separate solid and liquid phases, with the mesh size selected based on the properties of the drilling fluid and the size of the solid particles.

- Vibration motor: provides the vibration energy required by the shaker, usually installed on the vibration beam in the top.

- Shock absorber spring: supports the screen box and reduces the transmission of vibration to other equipment, ensuring the stable operation of the shaker.

- Base: The structure that supports the entire shaker, usually designed to be movable for easy installation and transportation.

-

Classification of Shale shaker

According to the vibration mode and working principle, Shale shakers can be divided into the following categories:

- Linear vibrating shale shaker: The vibration trajectory is linear, suitable for processing drilling fluids with large processing capacity and solid particles.

- Elliptical vibrating shale shaker: The vibration trajectory is elliptical, which can improve screening efficiency and is suitable for separating fine particles.

- Circular vibrating shale shaker: The vibration trajectory is circular, suitable for screening high viscosity drilling fluids.

-

Main functions of shale shaker

- Solid phase separation: Separate drilling cuttings and harmful solid phases from drilling fluid to maintain its cleanliness.

- Drilling fluid recycling: Recycling useful liquid phases from drilling fluid to reduce waste of drilling fluid.

- Equipment protection: prevent solid particles from entering downstream equipment (such as centrifuges, mud pumps, etc.), extending the service life of the equipment.

- Improve drilling efficiency: Clean drilling fluid can increase drilling speed and reduce the occurrence of drilling accidents.

-

Technical parameters of shale shaker

- Mesh size: usually 20-200 mesh, selected according to the properties of drilling fluid and the size of solid particles.

- Processing capacity: The amount of drilling fluid processed per unit time, usually 20-500 m ³/h.

- Vibration frequency: usually 700-3000 rpm, affecting screening efficiency and solid-phase separation effect.

- Amplitude: usually 2-8 mm, affecting the transport and screening efficiency of solid particles.

- Power: The power of vibration motors is usually 1-10 kW, depending on the size and processing capacity of the equipment.

-

Application scenarios of shale shaker

- Oil drilling: used for onshore and offshore drilling operations to separate drilling cuttings and solid phases from drilling fluids.

- Natural gas drilling: A shale shaker is also required in natural gas drilling wells to maintain the properties of the drilling fluid.

- Geological exploration: In geological exploration, shale shakers are used to separate rock debris and solid phases from mud.

- Environmental protection treatment: In the treatment of drilling waste, shale shakers are used to separate solid and liquid phases, reducing environmental pollution.

-

Maintenance and upkeep of shale shaker

- Regularly inspect the screen: replace damaged or blocked screen in a timely manner to ensure screening efficiency.

- Cleaning equipment: Regularly clean the screen box and vibration motor to prevent the accumulation of solid particles.

- Check the vibration motor: Ensure the normal operation of the vibration motor and replace damaged components in a timely manner.

- Lubrication components: Regularly lubricate the bearings and shock-absorbing springs of the shale shaker to extend the service life of the equipment.

-

Development trend of shale shaker

- Intelligence: The intelligent operation of the shale shaker is achieved through sensors and control systems, with real-time monitoring of screening efficiency and equipment status.

- Efficiency: Develop shale shaker with higher processing capacity and screening efficiency to meet the needs of complex drilling environments.

- Environmental Protection: Optimize the design of the shale shaker to reduce noise and vibration pollution to the environment.

- Modularization: Design a modular shale shaker for easy installation, maintenance, and transportation.

Summary

Oil drilling shale shaker is an indispensable equipment in the solid control system, which can effectively separate solid from drilling fluid, improve drilling efficiency and help save operation cost. With the continuous development of oil drilling technology, shale shakers are also moving towards intelligence, efficiency, and environmental protection, providing more reliable support for drilling operations.